Our Knowledgeable Team is Here to Help

If you need a complete range of rice cooker equipment and accessories, please contact us.

Contact UsTechnical Support

Our factory's technical support includes: pre-sales consultation, project planning, project budget, site planning, energy plan, video guidance or on-site installation and debugging, personnel training, simple repairs, daily maintenance and other services. We will provide customers with technical support with professional knowledge and technology, and solve customer problems and needs in a timely manner.

Make a form to indicate the installation, debugging, fault diagnosis, maintenance plan, etc. of the equipment;

Pre-sales support, send equipment operation videos and installation videos;

Communicate with customers by phone or video, and provide on-site guidance when necessary;

Organize daily after-sales service information;

Understand customers’ problems and needs immediately and solve them as soon as possible;

Learn from each other with customers, make breakthroughs in technology, and obtain maximum output with minimum investment;

In addition, we will inform customers of the need to strengthen the technical maintenance and management of mechanical equipment. Mechanical equipment is always in use from purchase to scrapping. During use, the policy of "focusing on maintenance, maintenance and use" should be adhered to, and should be used according to the specific use of the equipment. According to the situation, working environment, working conditions, etc., increase the content and frequency of maintenance appropriately.

Quality Control

The company takes high product quality as its core, continuously improves service brand awareness and customer satisfaction, and has passed ISO9001 quality certification; the four major measures of quality control refer to the four main methods and means used to control and manage quality, which are the following four point:

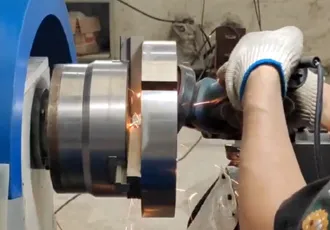

Inspection and testing

including visual inspection, dimensional measurement, functional testing, etc. of the product or service to ensure that it meets quality standards and requirements.

Process control

including monitoring and controlling the input, operation and output in the production process to ensure the stability and controllability of the process, thereby ensuring the stability of product quality.

Standardization

including the formulation and implementation of work standards, operating procedures, quality standards, etc., to ensure the consistency and standardization of work processes and reduce the occurrence of variability and defects.

Feedback and improvement

including establishing a feedback mechanism, continuous improvement and innovation to improve product quality and meet customer needs.

Our Knowledgeable Team is Here to Help

If you need a complete range of rice cooker equipment and accessories, please contact us.

Contact Us